Ductile Iron Pole

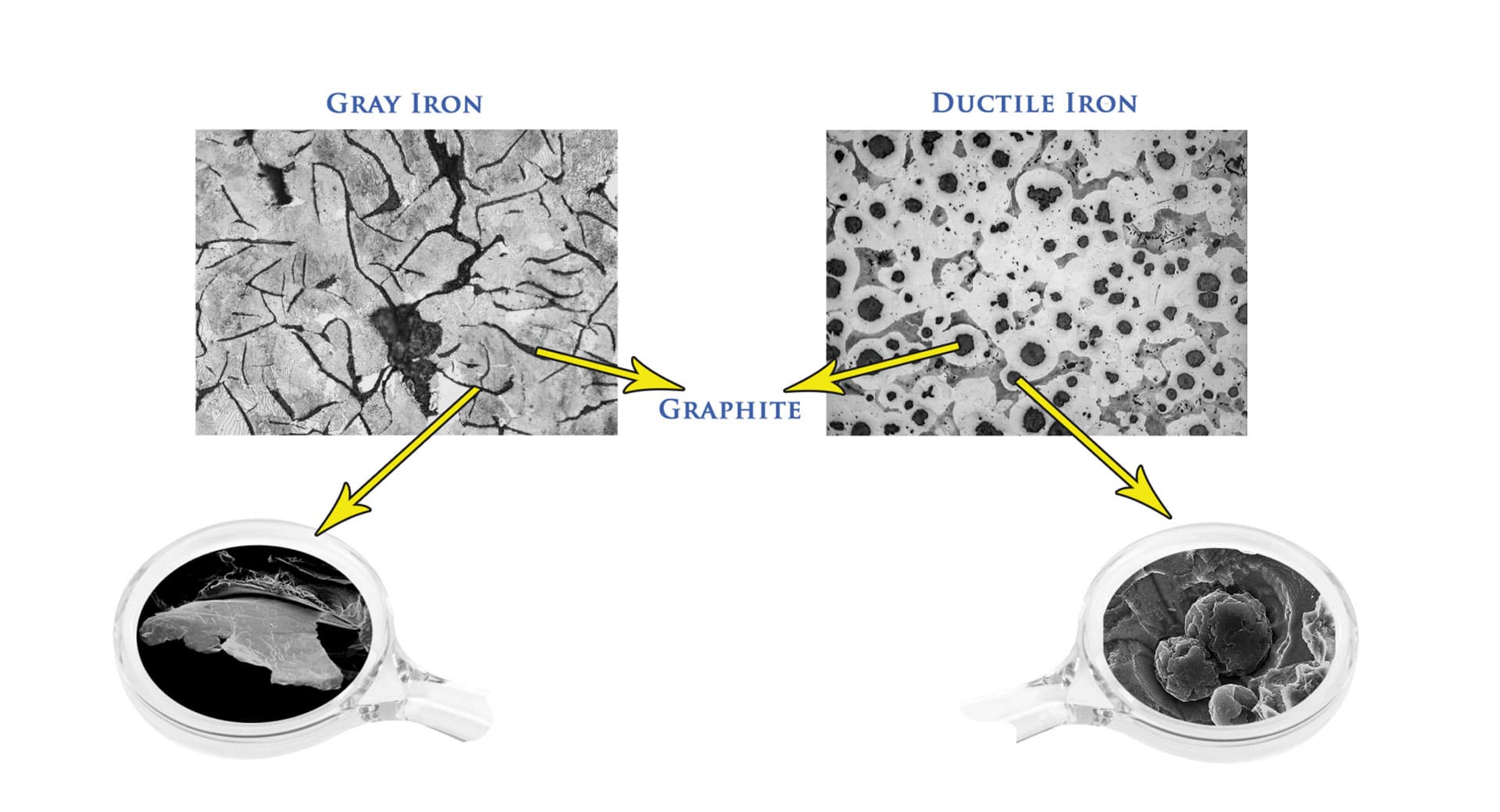

Ductile cast iron has free spherical carbon; however, carbon inside the cast iron has lamellar shape. Therefore, this type of carbon is sometimes called malleable cast iron and cast iron with spherical graphite (SG) in USA and UK respectively. Due to its proper characteristics, ductile cast carbon has gained a huge fame since its discovery namely 1948. Resistance against corrosion instinct of ductile cast iron is among advantages leading this metal to reveal an acceptable performance in environments exposing to corrosion. The protective layer formed on this metal while production process performs as a resistant later against corrosion. On the other hand, applying resistant covers coating with different characteristic including zinc coat, various paints such as Polyurethane, bitomen and epoxy and non-adhesive covers on the surface such as polyethylene sleeve could minimize the corrosion probability. Ductile cast iron pipes buried in soil are estimated life of 80 years.

Mechanical characteristics of ductile cast iron

Minimum yield tensile strength : 270 MPa

Minimum tensile strength : 410 MPa

Minimum percentage of elongation (A): 10

Minimum of elasticity module: 165 CPa

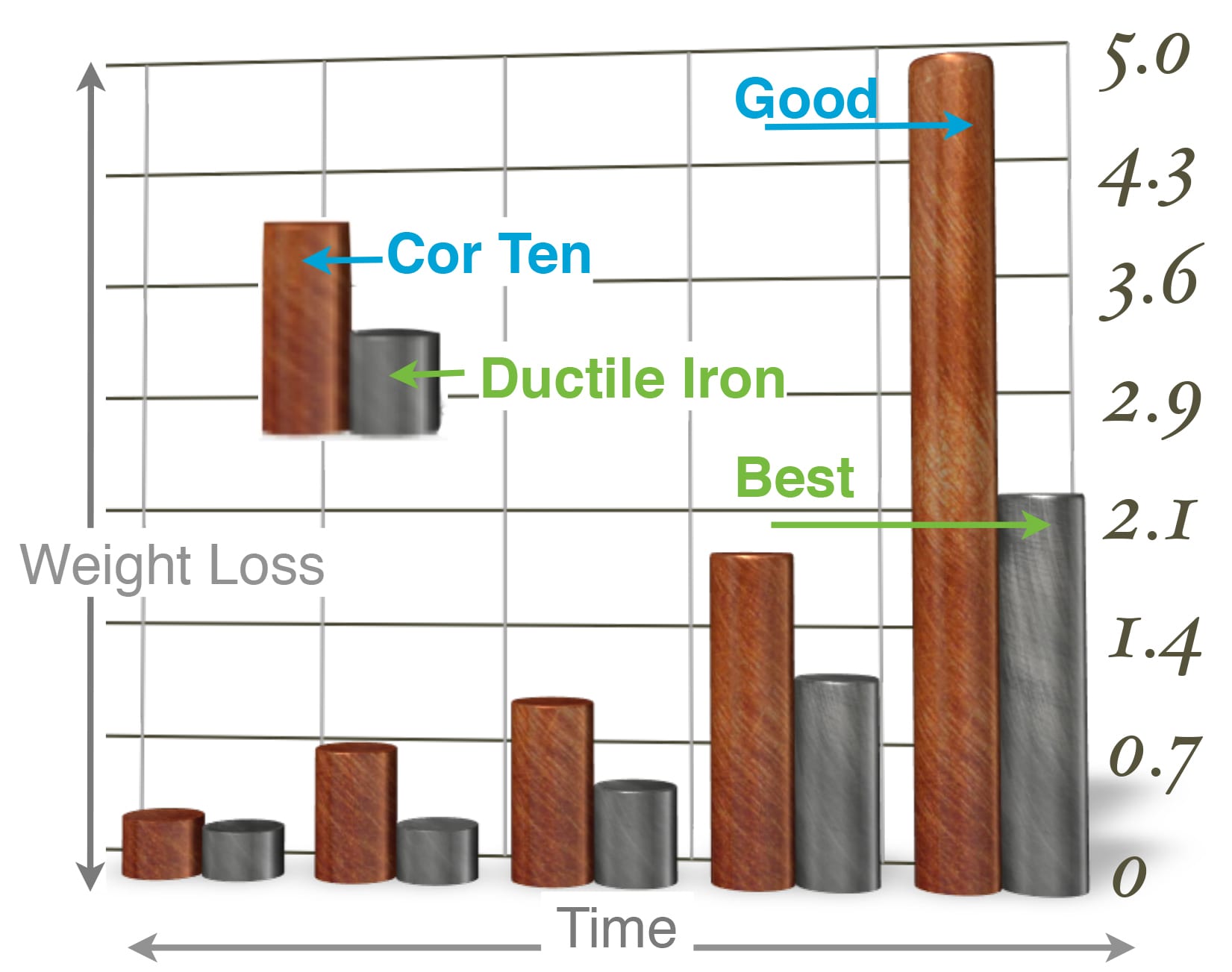

The salt spray test was carried out according to ASTM B117. Results of tests show that the corrosion rate of ductile iron is about half in comparison with A588 weathering steel.

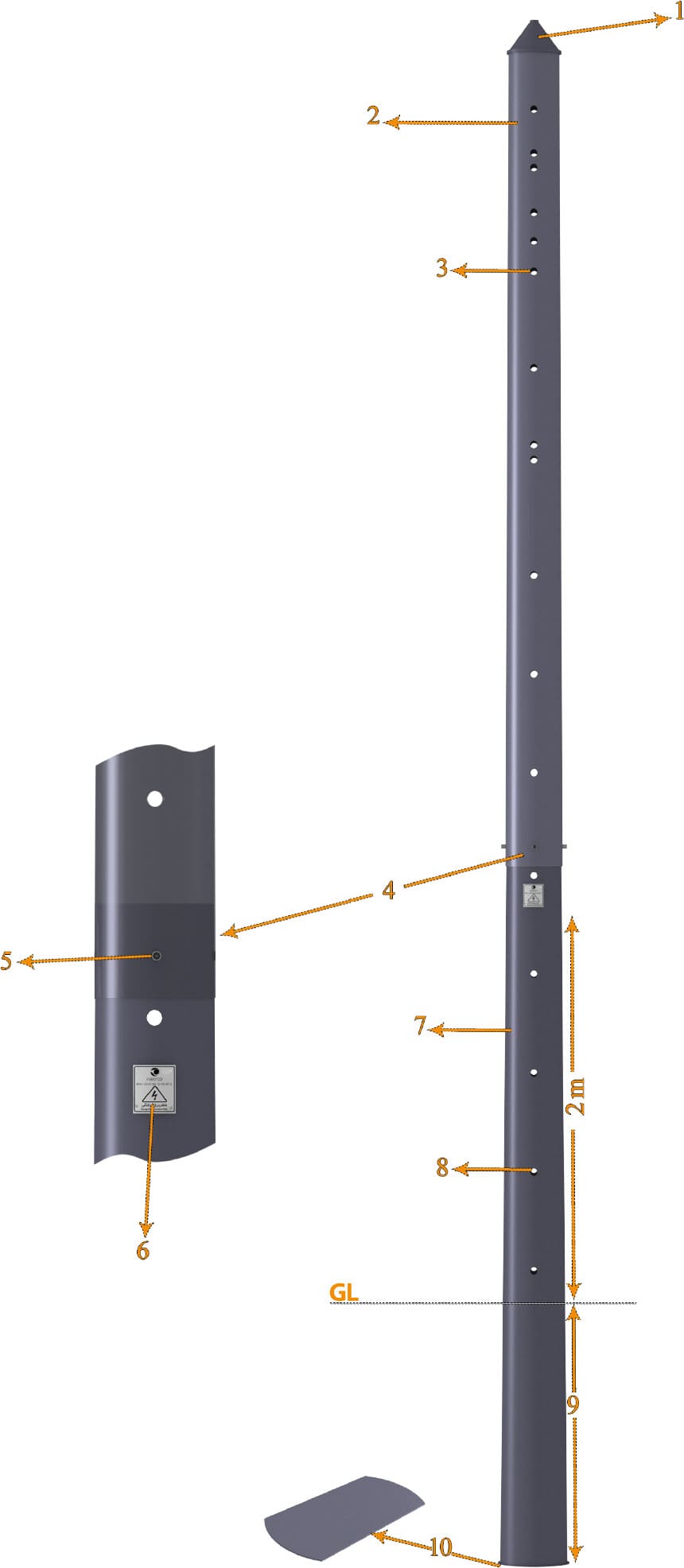

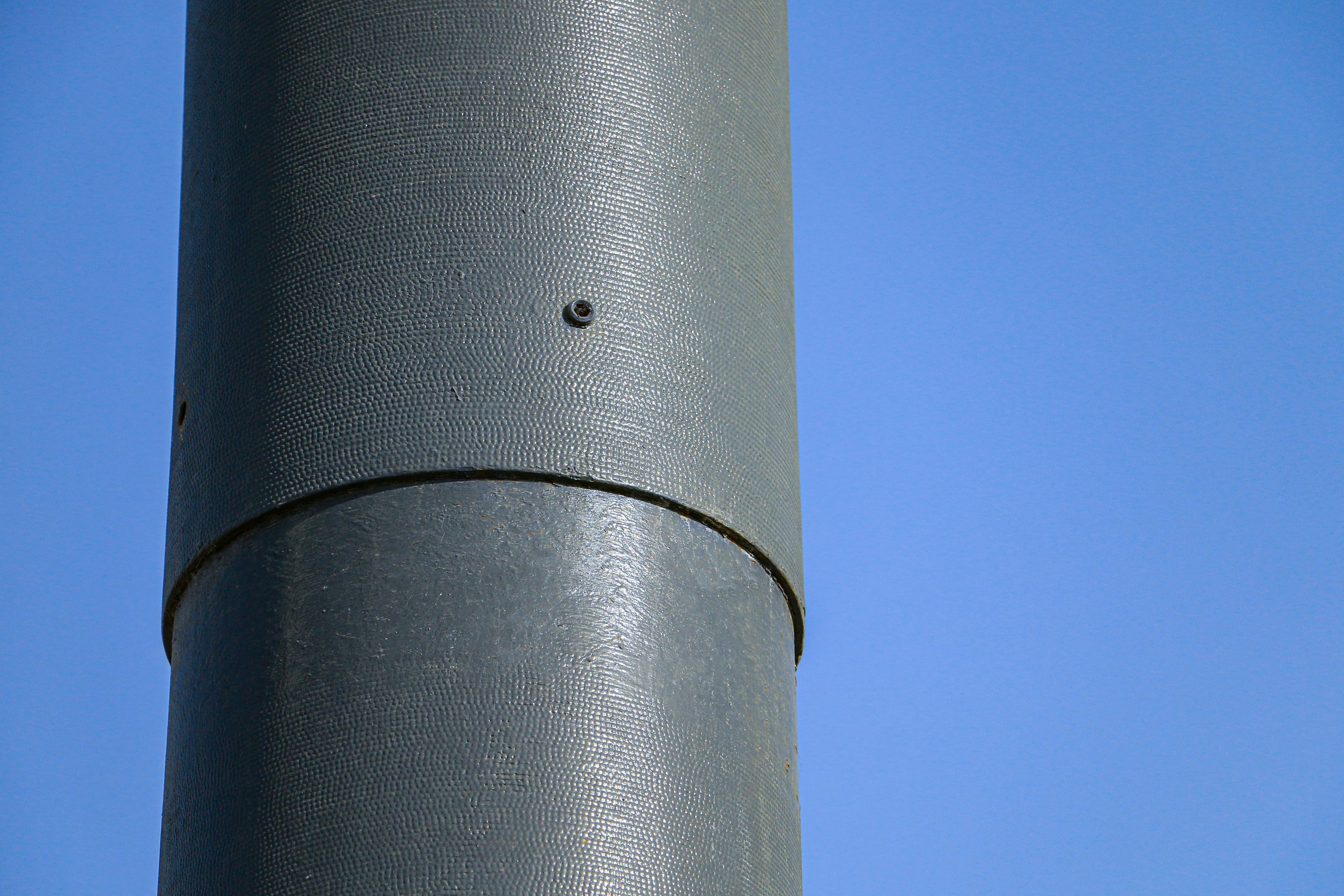

Ductile cast iron pole segments

Specification plate

Irans power generation and distribution company (Tavanir) a plate carrying unique specifications of each pole is allocated, in order to identify the electricity poles following the installation in site. This plate consists of pole’s identification number based on instruction titled “Coding of electricity distribution networks equipment”. The identification number specifies the manufacturer code, equipment code, production year and month and unique sequential serial number for each pole.

Each pole can be traced during its lifetime, considering the universal tracing system in Hamoun Nyzeh Company. All the controlling and quality records of poles have been registered in this system and are accessible from any time .

Applications of ductile cast iron pole

• Applicable in 33Kv and 20 Kv lines

• Regions with high corrosion and humidity

• Regions having corrosive soil

• Tensile poles used in extremity and angles of distribution lines

• Enhancement the existing distribution line

• Lighting pole

• Transformer installation pole

• Applicable in telecommunication equipment and warning signs

Advantages of ductile cast Iron

• Presented in various classes compatible with existing wooden and concrete poles.

• Life time over 80 years in respect to special applied coating on the pole (through proper strength and resistance against corrosion).

•15 years of guarantee.

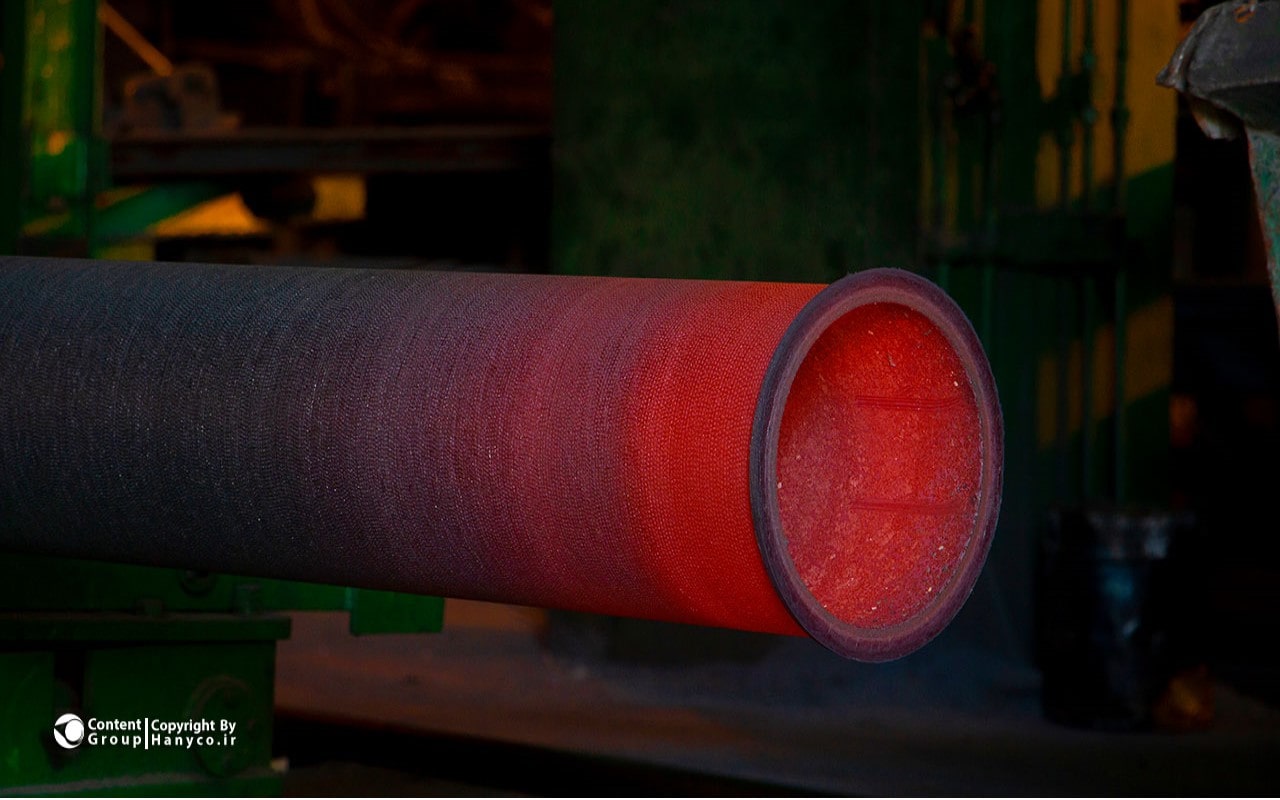

•Integrated body (Without weld seams in its body / pole formed through the process of centrifugal casting).

• Easy carrying and installation due to its low weight (30 percent of concrete poles weight in similar class).

•Beautiful appearance in urban furniture in different colors.

• Resistance against firing and destruction caused by insects.

• Recyclable raw materials used in ductile cast iron pole, make it to high valve product (green product).

• Easy pole body drilling even on installation site.

• Suitable for impassable regions due to the pole assembly capability in installation site.

• Suitable for regions with variable climate such as snow and frost.

• Short production and casting time for each pole (less than two minutes).

Accessories

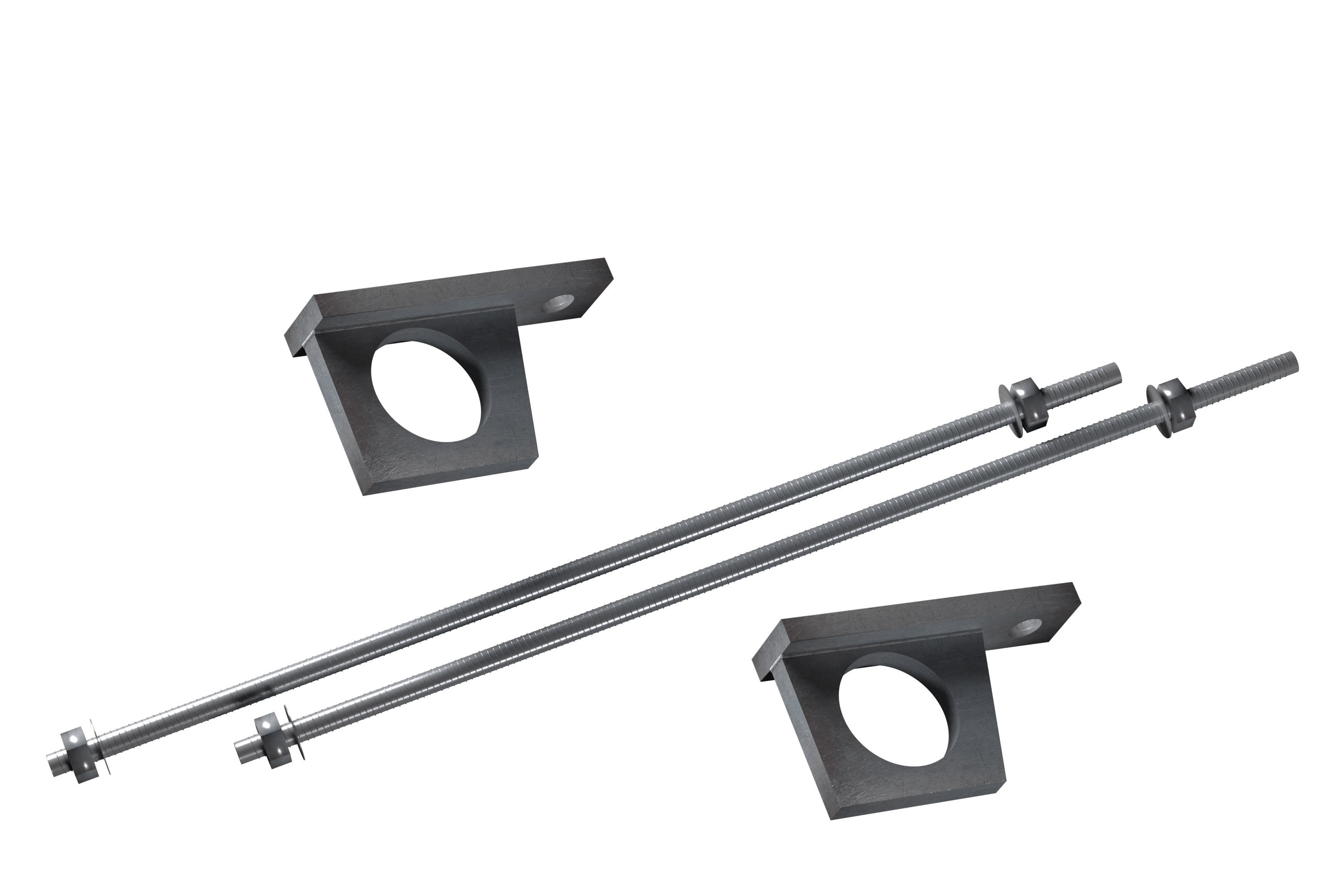

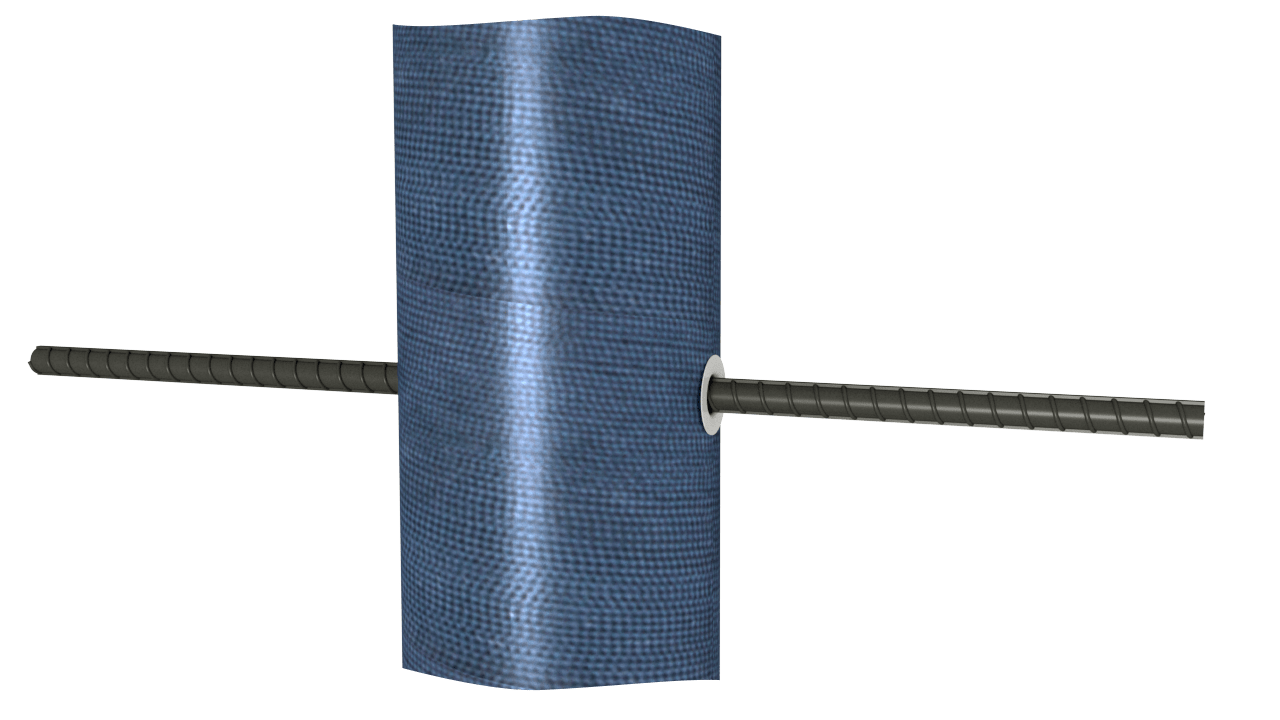

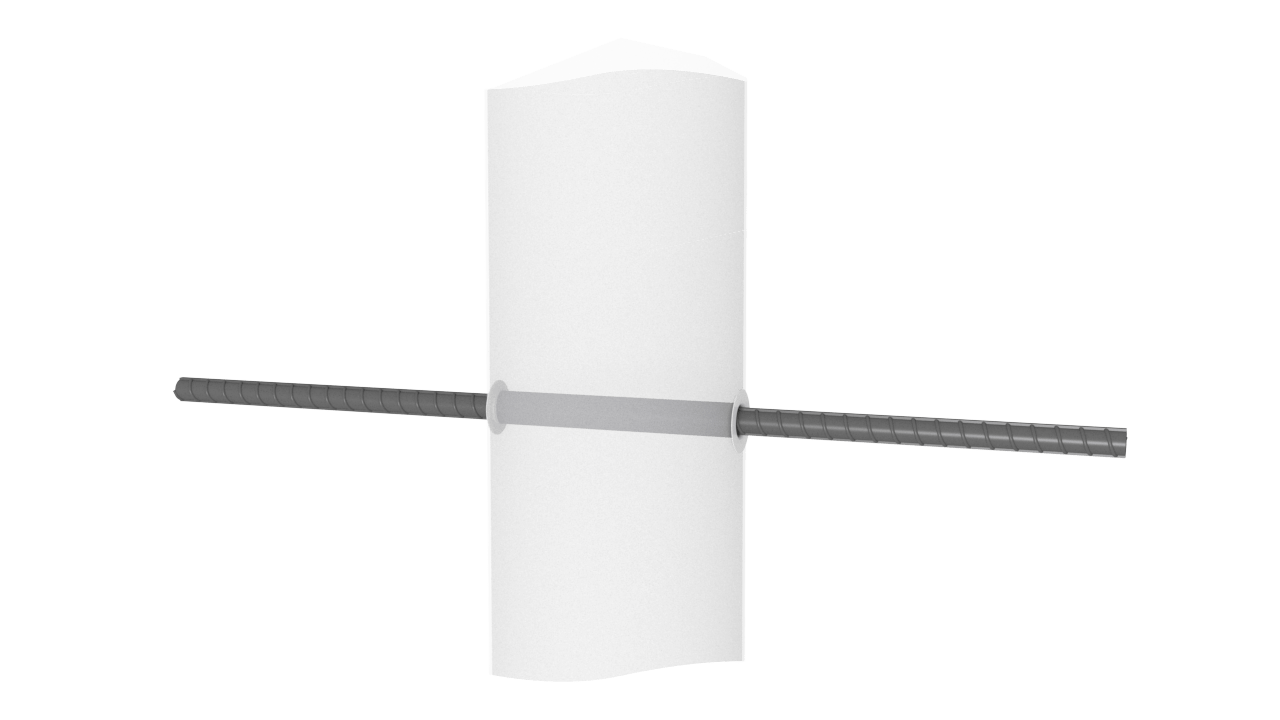

1- On-site pole assembly

Ductile cast iron poles are capable to be assembled on customers site. Assembly ring has been designed for this reason.

2-Installation without crane

One of the advantages of ductile cast iron poles is the capability of installation and assembly of these poles without using crane and manually within impassable regions, due to the light weight of poles as well as the two or three-sectioned pole.

3-Ascension stairs instructions

Ascension stairs instructions are offered for the purpose of ease and reduction the ascension time from pole (Stainless, Galvanized or polymerized steel).

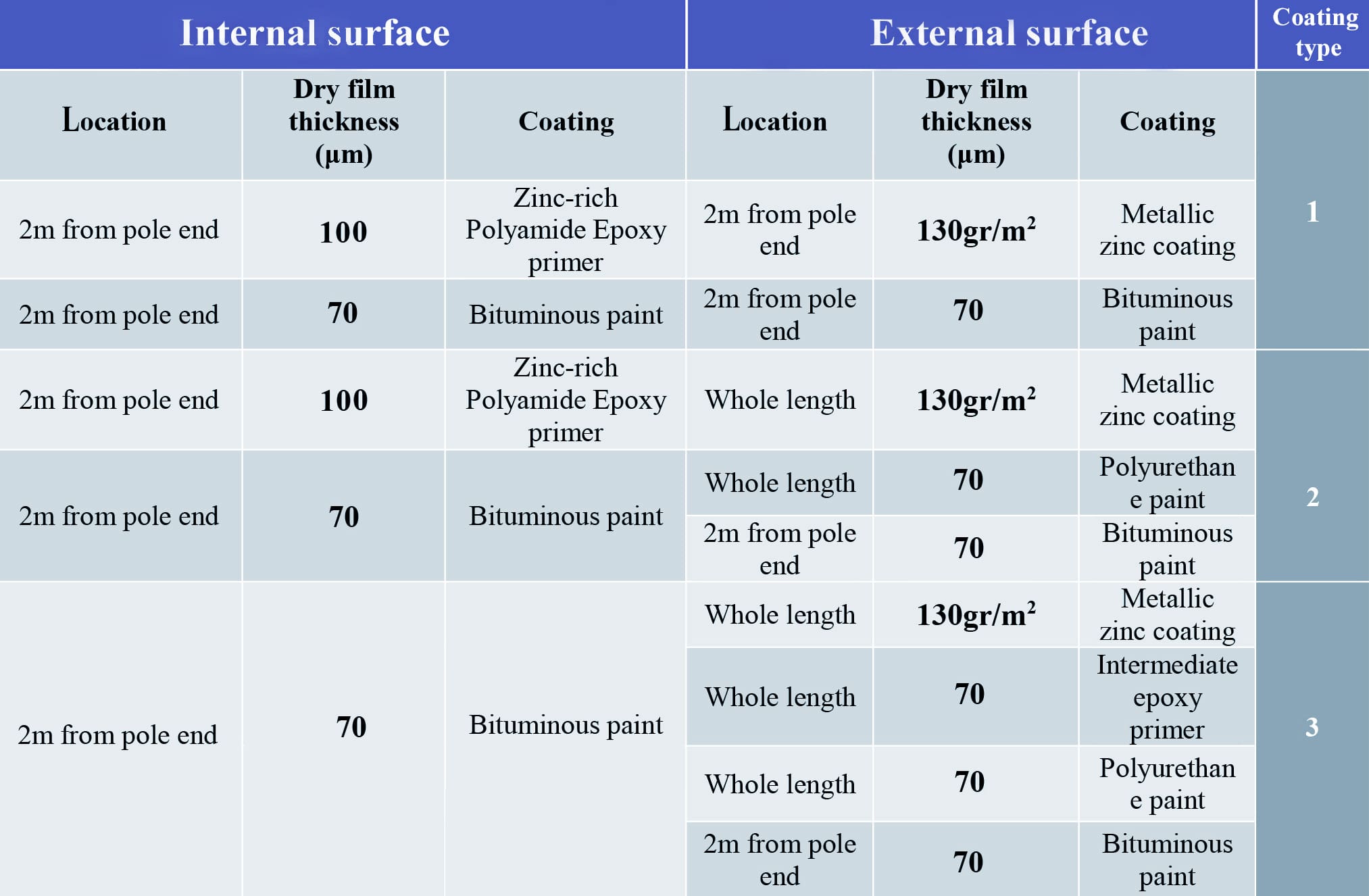

Coverage classes provided based on climate conditions of pole’s installation place

Ductile cast Iron poles coatings

Burial Segment Body Segment Coverage classes provided based on climate conditions of pole’s installation place Various types of resistant coatings against corrosion are applied on and conical poles, based on type and place of application. The burial section of pole is always covered by corrosion-resistant covers. However, the upper-ground section of pole could be deigned without any covers, due to the natural resistance of ductile cast iron against corrosion. Therefore, the oxidative layer could give a distinctive and beautiful appearance to the pole as well as protecting the pole metal and is not considered as a threat within pole’s lifetime. Moreover, it is possible to offer coatings in different types and colors based on the climate conditions and customer’s demands.

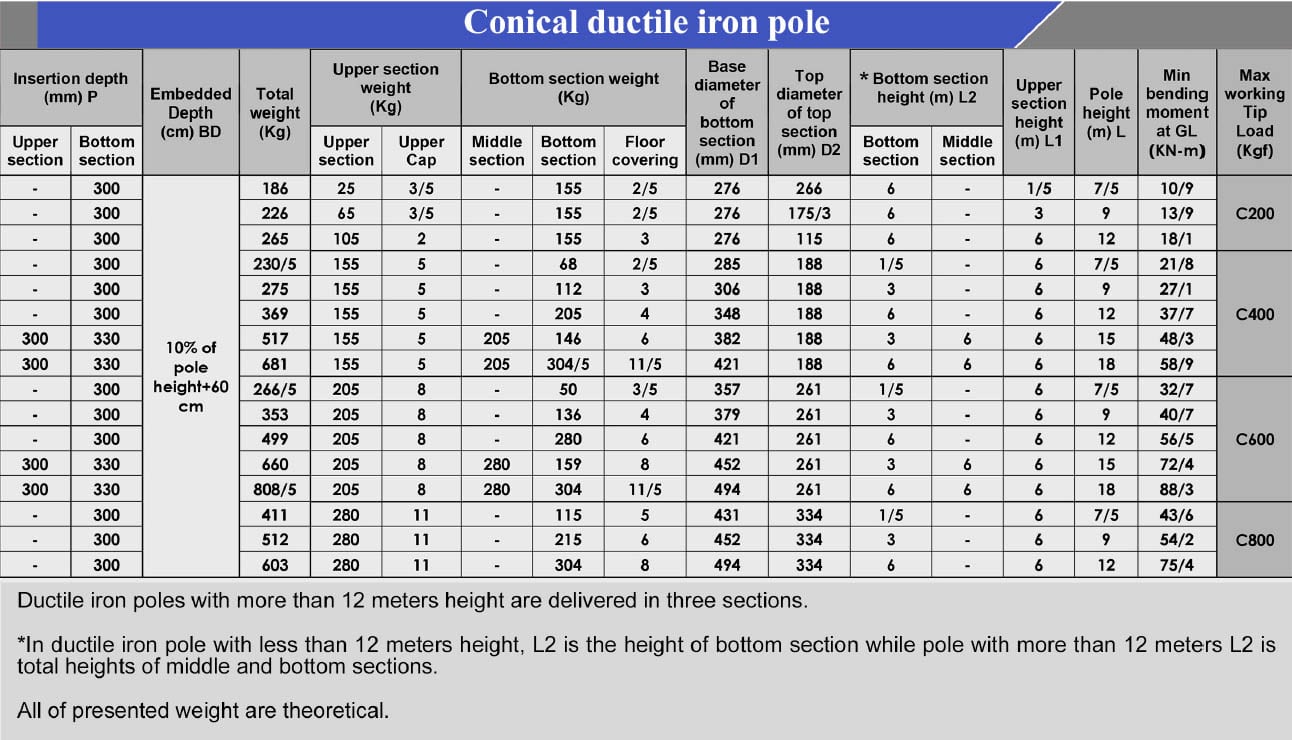

Technical specifications of conical electricity poles

Performance tests

1. Ductile cast iron poles are tested from the point of performance up to three (3) times the maximum permitted workforce, and passed successfully all the relevant tests. These tests were performed by the reference laboratory of power research institute.

2. Ductile cast iron poles performance was examined using “finite element software”, and the obtained results were verified using practical tests.

Electricity conductivity tests

According to the conductivity test performed by Iranian Niroo research institute (NRI), the conductivity amount of ductile cast iron poles is equal to a copper 4 wire. The Earthing (grounding) system of ductile cast iron poles is made through the earth screw embedded on the pole body which is made of stainless steel. The earth screw height from ground can be determined by the customer upon request.

Standards

Ductile cast iron poles are produced according Tavanir Company instructions titled “Instruction for requirement technical criteria and performance tests of ductile iron poles”. Moreover, ductile cast iron poles are test from the point of performance, according to Tavanir instructions and national and international standards. Hamoun Nyzeh is the exclusive producer of ductile cast iron distribution poles in Iran.

Final words

Using novel technologies in Water and Electricity industry does not only make us committed to supply and establish fundamental infrastructures, but also could bring about a brilliant future for next generations. This is the crossbar switch of industry and our patriotism, where obliged ourselves to become the third producer of ductile cast iron distribution poles in the world, relying on our experience for several decades on centrifugal casting of ductile cast iron pipes as well as our engineering team. The poles whose stability and antiquity could be more than a century and could be protected against any types of damage such as climate condition, heat, fire, frost and snow.

Moreover, we realize our social responsibility regarding environment by producing green and recyclable products and preventing directly or indirectly from deforesting and adding non-recyclable materials to the nature. Now ductile iron poles are used widely in Iran and some countries in harsh environment corrosive areas. Thanks to their lighter weight Hanyco ductile iron poles are also less expensive to transport and install. we hope with developing this product, the electricity industry converts to more engineering, cost effective and safer industry in world.

Tags