L.Pipe

Suitable alternative for polymeric pipes in drinking water distribution network

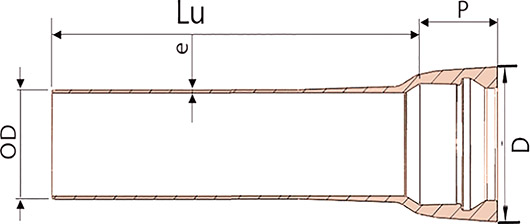

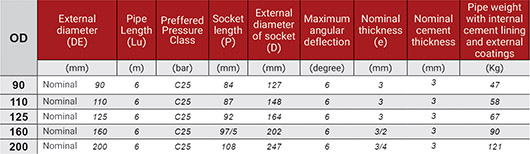

Dimensions and weights specifications of L.Pipes according to ISO 16631

It is noteworthy that the amount of weight reduction in L. Pipes is 40 to 50 percent comparing to normal ductile iron pipe.

L.Pipe assembly and disassembly

Assembling and disassembling of this product is similar to Tyton pipes, except that the assemblage required force is less, which can often be carried out with a hand lever due to the lower weight of these pipes, especially in smaller sizes. Therefore, it is recommended to use the least amount lubricant as possible during assembly and installation operations. In this case, it'd better to primarily apply lubricant on the pipe's spigot and consequently perform assembly, after making sure of cleanness of the socket.

Other specifications and type of internal and external coatings of L.Pipes

:: Type of external coatings: External coating of metallic zinc (200 gr/m2) and finishing layer of green epoxy/polyurethane with the minimum thickness of 70 microns according to ISO 8179 Standard

:: Type of internal lining: Portland cement according to ISO 4179 and EN 598 standards

:: Sealing gasket type: Polyethylene fitting's gasket

How to order and store the product

Due to the less wall thickness of these pipes, it is recommended to order and convey this product in packing. Moreover, it is proper to use four-sided woods while unloading and storage.

Ductile iron pipes compatible with plastic {PVC or PE) piping systems

Higher reliability in urban and rural water distribution networks

Light pipe is a new generation of ductile iron pipe with less wall thickness than conventional ductile iron pipes. Thus, due to significant decrease of weight, it is more engineering, cost effective and logical using them in drinking water distribution network. Since ductile iron is preferred option for drinking water lines, The L. Pipes have been the best alternative for polymeric pipes in drinking water distribution lines. It also eliminates several deficiencies and limitations existing in the polymeric pipes, such as restrictions on outdoor maintenance and storage, environmental issues, high repair and maintenance costs due to fracture and leakage of the polymeric pipes, and so on.

Standards:

:: L.Pipe is manufactured with the nominal wall thickness of 3 to 4 millimeter, according to ISO 16631.

Applications:

:: In regions with limited access to which it is rarely possible to carry pipes with usual weight

:: Proper alternative for polymeric pipes in drinking water distribution network

:: The best choice in distribution lines with low working pressure

Advantages:

:: Prevention from transferring dangerous chemical compositions to the drinking water

:: Eliminate the limitation of maintenance and storage in open area of polymeric pipe

:: Decrease water leakage and waste in network due to using polymeric pipe

:: Much easier storage and transferring comparing to polymeric pipes

:: Compatible with environment and its relevant requirements

:: Easy leakage-tracing due to conductivity of pipe body

:: Easy installation, usage and cutting in customer site

:: Proper angular deflection up to 6 degrees

:: A green product with high scrub value

:: Less fracture in distribution network

:: Impossibility of illegal branching

:: Less repair and maintenance

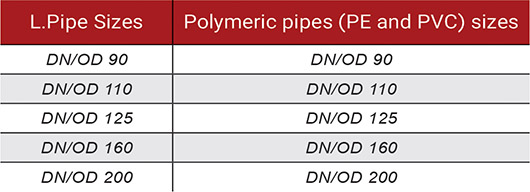

Conformity of DN/OD Sizes of L.Pipe and polymer pipes

Tags