Tyton Pipe

The best in drinking water transmission

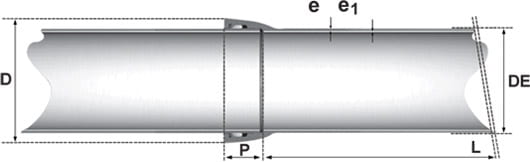

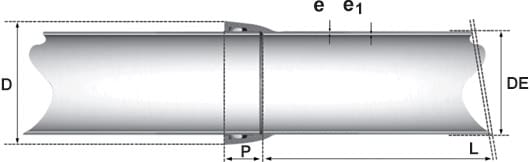

Push-on Joint (Tyton)

One of the most common type of joints, used for ductile iron pipes is Push-On joint (Tyton) which can be assembled easily and quickly. This joint includes a rubber gasket with a special material and design that placed inside the socket of pipe so that the next pipe's spigot could fit into socket by pressure and get assembled and sealed at the same time. These sealing gaskets are made of EPDM according to ISO 4633 and EN 681.

advantages

:: Easy and fast installation, without special equipment and expert manpower

:: Not require welding and using bold and nut

:: Proper angular deflection

:: Perfect sealing

This joint is designed in a way that could provide a maximum 5 degrees of angular deflection.

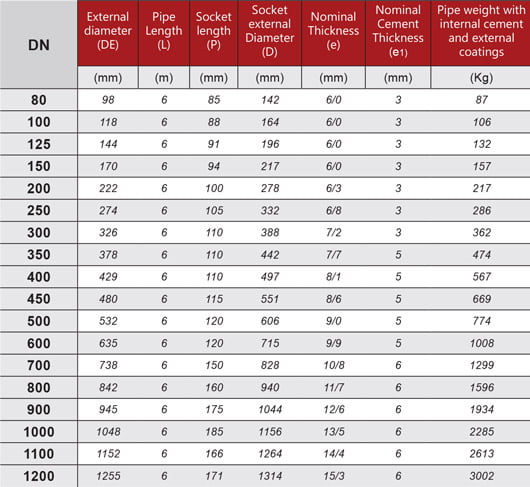

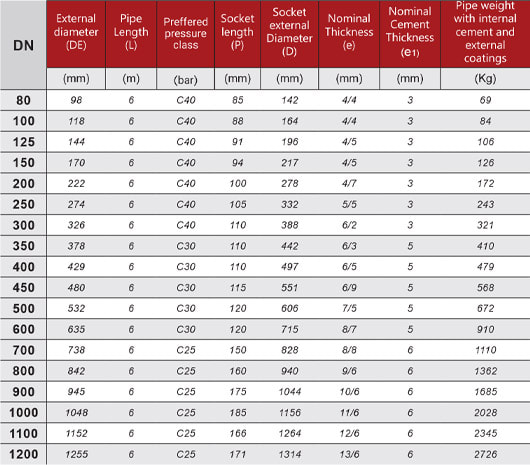

Dimensions and weights specifications of ductile iron pipes according to ISO 2531 Standard

Push-on joint (Tyton) Pipe according to ISO 2531:1998 K class

Push-on joint (Tyton) Pipe according to ISO 2531:2009 C class

Tags