Ductile Iron Manhole

Manhole is generally used for cleaning, inspection and checking equipment, periodical maintenance, etc. The circular metal plates that are seen in streets are manhole lids. The most important function of manholes is to provide access point for different sections of the sewage network. Also, they are used to access underground cables in telecommunication systems.

Manholes are typically made of ductile or cast iron, concrete, composite, etc. Given the long lifespan of ductile iron, it is considered as one of the most cost-effective materials. Manholes are classified based on the applied force on them and the condition of usage.

One of Hanyco’s products is Manhole made of ductile iron manufactured by a fully automatic lost foam casting production line. These manholes are designed and examined based on the simulations by finite element software and performance tests according to national and international standards.

Application

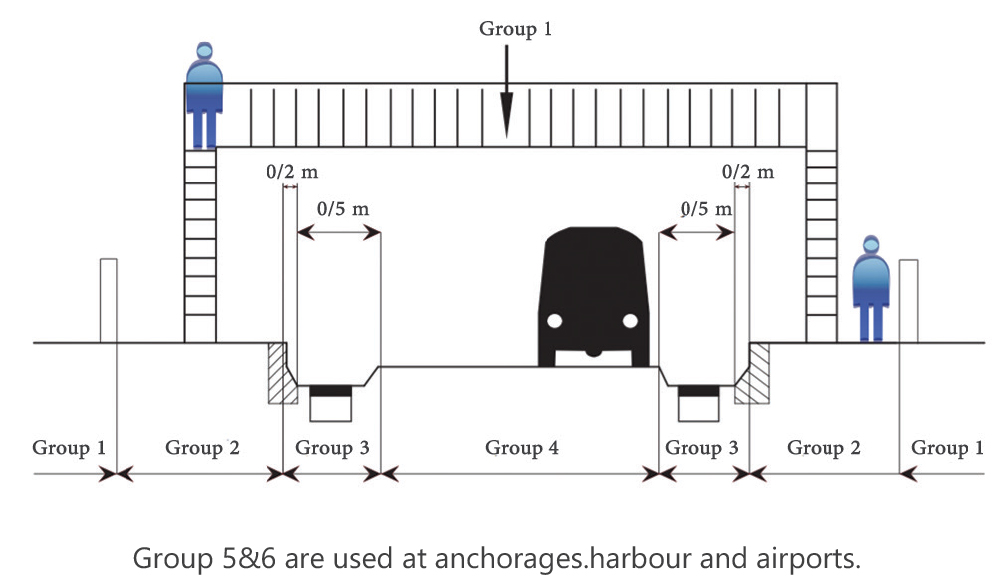

The appropriate class of a manhole top or a gully top to be used depends on the place of installation. Various places of installation have been divided into groups numbered 1 to 6, as listed below.

Group 1 (A Class): Areas that can only be used by pedestrians and pedal cyclists. (Maximum force allowed: 15 KN)

Group 2 (B Class): Pedestrian areas and comparable areas, car parks or car parking decks. (Maximum force allowed: 125 KN)

Group 3 (C Class): For gully tops, installed in the area of kerbside channels of roads which, when measured from the kerb edge, extends a maximum of 0,5 m into the carriageway and a maximum of 0,2 m into the pedestrian area. (Maximum force allowed: 250 KN)

Group 4 (D Class): Carriageways of roads (including pedestrian streets), hard shoulders and parking areas, for all types of road vehicles. (Maximum force allowed: 400 KN)

Group 5 (E Class): Areas imposing high wheel loads, e.g. docks, aircraft pavements. (Maximum force allowed: 600 KN)

Group 6 (F Class): Areas imposing particularly high wheel loads, e.g. aircraft pavements. (Maximum force allowed: 900 KN)

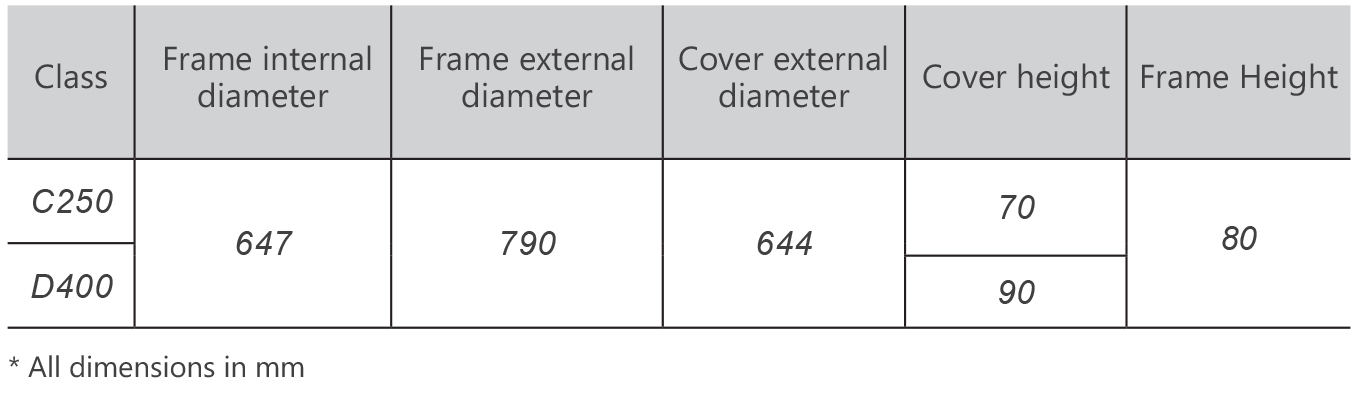

It is noteworthy that HANYCO produces ductile iron manhole in two different classes C250 and D400.

Manhole Standards

1- EN124-1: 2015: Gully tops and manhole tops for vehicular and pedestrian areas: “Part-1: Definitions, classification, general principles of design, performance requirements and test methods”.

2- EN 124-2:2015: Gully tops and manhole tops for vehicular and pedestrian areas: “Part-2: Gully tops and manhole tops made of cast Iron”.

3- Iran national standard INSO 14976, “Gully tops and manhole tops for the vehicular and pedestrian area

Technical specification of ductile iron manhole tops

Advantages of ductile iron manhole

:: Suitable for use in regions with harsh environmental conditions

:: Suitable for regions with high traffic loads and high-speed transportation.

:: Long service life and high strength.

:: High resistance against corrosion

:: Adequate resistance against shock.

:: A green product with high scrab value

Product safety

To increase the product safety while the top is closing, it has been designed in a way that it closes to about 60° and then halts. To fully close the lid, it should be pulled forward and fully closed. This mechanism prevents the sudden fall of the lid and the user’s injury. The pin of hinge is welded to the manhole's frame body to minimize the possibility of theft.

Shock and noise damper gasket

HANYCO’s Ductile iron manhole tops are equipped with a shock and noise damper gasket.